14 November, 2025

What is Battery Cycle Life? Definition, Calculation, Factors, and How to Extend It

As energy storage systems, electric vehicles, and lithium-ion technologies rapidly expand worldwide, battery cycle life has become one of the most critical indicators of battery performance. Whether used in consumer electronics, EVs, or stationary energy storage, cycle life directly determines a battery’s service life, economic value, and long-term reliability.

Understanding battery cycle life helps users evaluate different battery options and allows system designers to build more durable, economical, and environmentally friendly solutions.

This article provides a complete overview of what battery cycle life is, how it is measured, why it matters, the factors that affect it, and how to extend battery life in real-world applications.

What is a PCS?

Battery Cycle Life refers to the number of charge and discharge cycles a battery can complete under specified test conditions before its capacity or power degrades to a certain percentage of its initial value. The industry-standard threshold is 80%. This means a battery’s cycle life is considered complete when its capacity degrades from an initial 100% to 80%.

For a battery with an initial capacity of 1000Ah, its cycle life is the number of cycles it completes before its capacity drops to 800Ah.

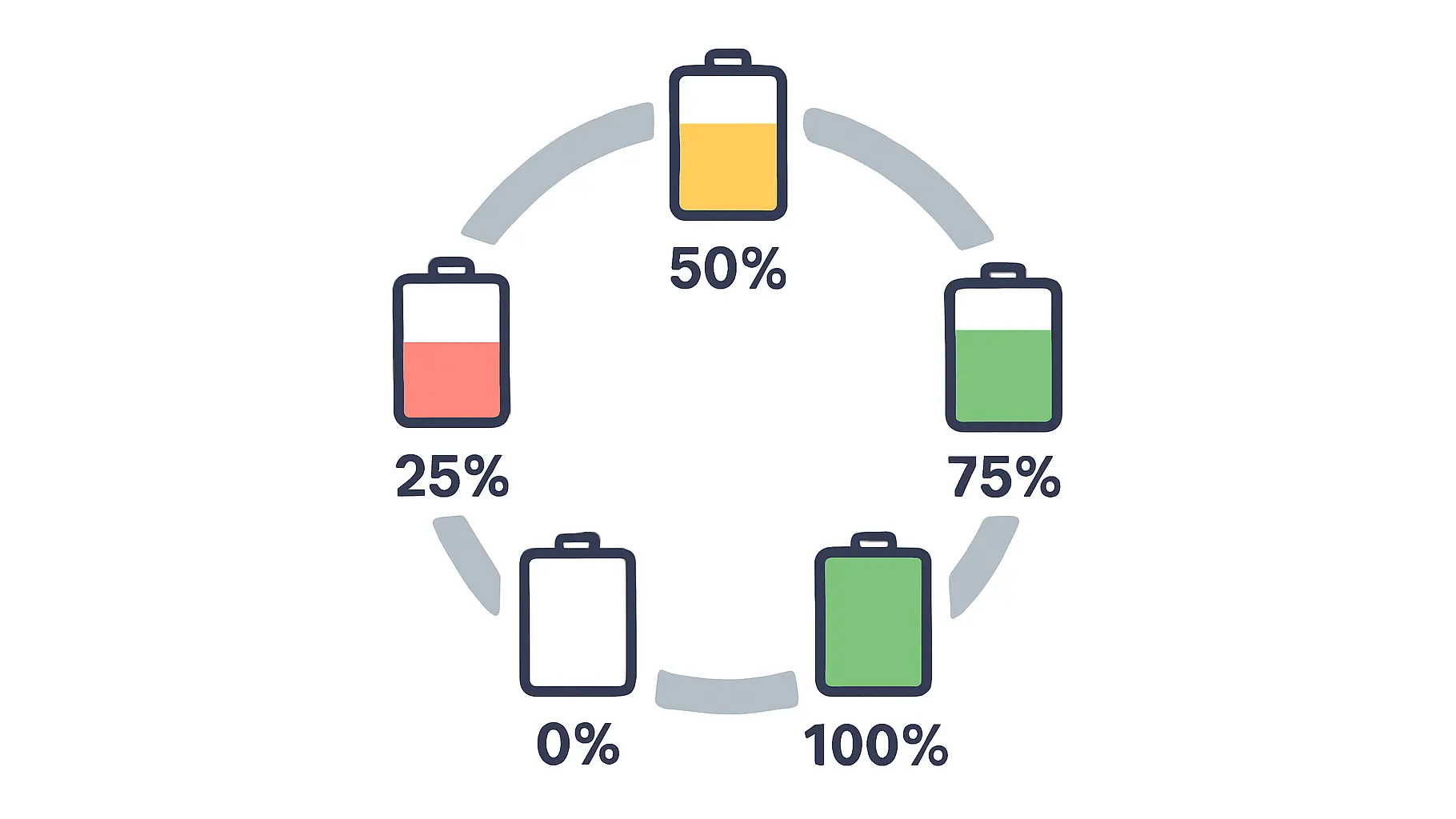

A full cycle is defined as the process where the cumulative discharge reaches 100% of the battery’s rated capacity, regardless of the number of individual charges.

For example: If you use 60% of the battery’s capacity one day, recharge it fully overnight, and then use 40% the next day, the cumulative discharge is 100%–thus completing one cycle. Simply put, one cycle is completed when the total discharged energy equals 100% of the battery’s capacity.

Why Battery Cycle Life Matters?

For users aiming to maximize performance, minimize degradation, and extend service life, understanding the importance of cycle life is crucial. In consumer electronics, EVs, or residential and utility-scale energy storage systems, cycle life directly dictates long-term reliability, economics, and usability.

Impacts Product Lifespan and User Experience

A longer cycle life means the battery can operate reliably for a longer period before its capacity degrades to an unusable level.

- Electronics: Provides more stable battery life and a longer product lifespan.

- Energy Storage Systems : Cycle life determines the economic viability of the project.

- EVs: The battery pack is the most expensive component. A longer lifespan improves overall economics and boosts consumer confidence.

Therefore, cycle life not only affects user experience but also determines the long-term value of the device.

Determines Total Cost of Ownership

Cycle life directly impacts the long-term operating cost.

For example: In an ESS, if the battery cycle life is only 2,000 cycles, it might require replacement within a 10-year project life cycle, leading to high maintenance costs.

If the cycle life reaches 6,000 cycles or more, although the initial investment might be higher, the long-term LCOE is lower, offering better economics.

GODE’s 1907 ESS, with healthy temperature management, controlled State of Charge (SOC) range, and reasonable C-rates, can achieve a cycle life of 6,000+ cycles. This makes it a stable power source for microgrids and off-grid applications, representing a high-return long-term investment.

Environmental and Humanitarian Concerns

Longer cycle life means fewer battery replacements, less raw material consumption, a lower environmental burden, and better alignment with global sustainability goals.

Long-life batteries contribute to:

- Reduced frequency of battery replacement

- Lower pressure on resources during manufacturing

- Decreased waste volume for disposal

- Reduced demand for mining critical minerals like lithium, nickel, and cobalt

The issue of cobalt resources deserves particular attention. The Democratic Republic of Congo holds over 50% of the world’s cobalt reserves, and cobalt is a key material in power batteries and electronics. However, ASM sectors often involve severe child labor exploitation.

Extending battery cycle life not only reduces reliance on critical minerals like cobalt but also represents a responsible humanitarian stance towards protecting children and vulnerable groups.

How To Calculate Battery Cycle Life

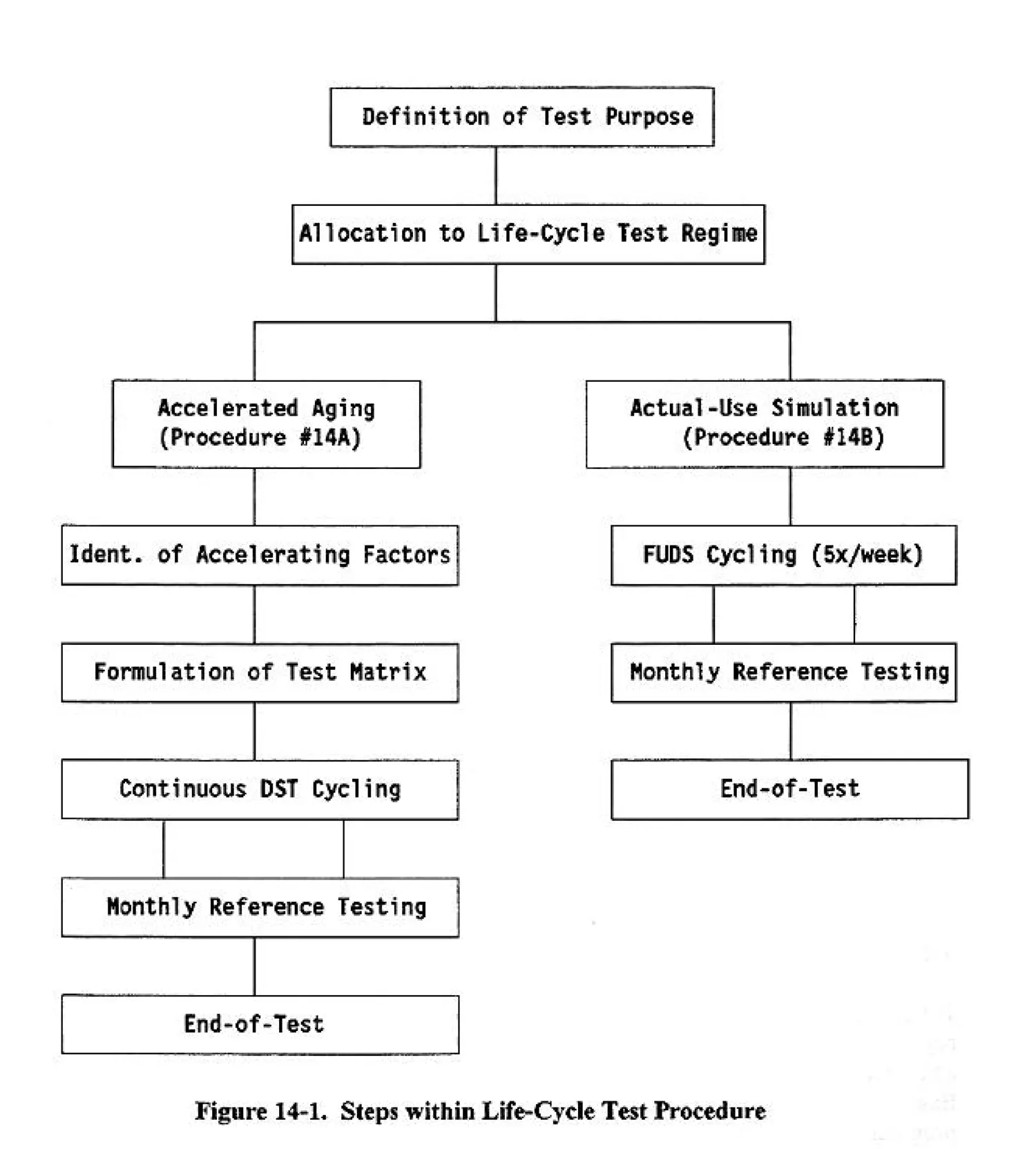

Battery cycle life isn’t simply the sum of charging times; it’s a scientific testing method based on authoritative standards, strict procedures, and clear criteria. According to the U.S. Advanced Battery Consortium (USABC) Battery Test Manual, the complete calculation process involves the following steps:

Step1: Initial Baseline Test

At a specified temperature (typically 25°C or 30°C) and discharge rate (e.g., C/3), perform a standard discharge on a fully charged battery to measure the initial capacity (C_initial), which serves as the benchmark.

Step2: Perform Cycle Testing

Conduct repeated cycles according to the set test profile, for example:

- 100% or 80% DoD

- Fixed C/3, C/2, etc.

- Constant temperature environment

At regular intervals (e.g., every 25 or 50 cycles), repeat the baseline test procedure to measure the current capacity (C_current).

Step3: Data Recording and Endpoint Determination

Continuously record capacity fade and calculate the Capacity Retention:

Capacity Retention = (C_current / C_initial) × 100%

The test concludes when the Capacity Retention first falls below 80%.

The total number of cycles accumulated at this point is the battery’s cycle life under those specific conditions.

Step4: Key Professional Note

Cycle life is highly dependent on test conditions.

Different temperatures, DoD levels, and C-rates can lead to significant variations in the reported cycle life. Therefore, professional cycle life reports must clearly state:

- Temperature

- DOD

- C-rate

- Voltage window

- Ambient conditions

For example: “Cycle life≥3000 cycles at 25°C, 80% DoD, C/3 charge/discharge rate.” Discussing cycle life without stating the test conditions is meaningless.

What Affects Battery Cycle Life?

Cycle life is influenced by multiple factors. Understanding these is crucial for system design, battery selection, and daily usage.

Battery Chemistry

Different chemistries inherently have different lifespans.

- LFP: Stable structure, minimal volume change, long life, often exceeding 3,000 cycles.

- NMC: High energy density, but less structural stability under deep cycling, typically shorter life than LFP.

- Lead-acid: Short lifespan (300–500 cycles), more suitable for starting applications than deep cycling.

Temperature

Battery capacity degradation is closely related to temperature. Degradation is minimal at room temperature but accelerates during storage or use at high temperatures (typically above 35°C) or low temperatures (typically below 5°C).

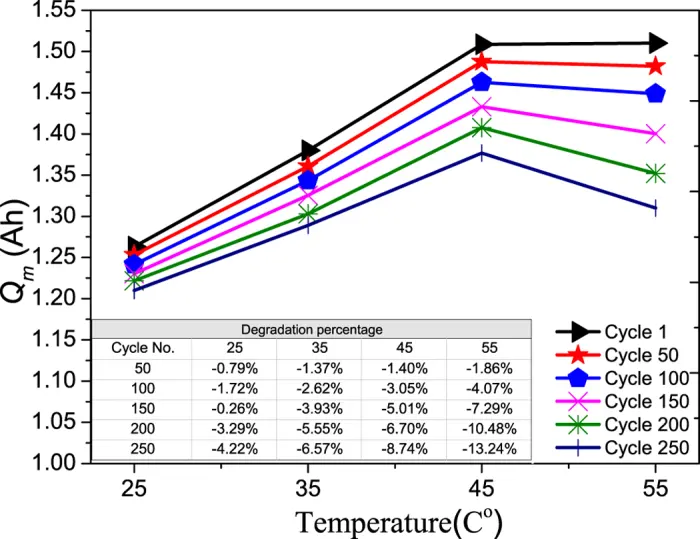

A study published in Scientific Reports found that while maximum storage capacity increased as temperature rose from 25°C to 45°C, it began to decrease with further temperature increases.

Given that performance degradation is more severe at high temperatures, prolonged exposure to extreme heat significantly shortens battery life. Avoid prolonged high-temperature exposure.

Depth of Discharge

DoD refers to the percentage of the battery’s total capacity discharged in a single cycle. It is one of the most user-controllable factors for extending life.

Frequently charging to above 90% and discharging below 10% can accelerate capacity fade.

Avoid running the battery until it shuts down before recharging. Topping up the battery regularly is a better habit.

C-rate

The C-rate measures the charge/discharge current intensity. While high-current charging/discharging meets the need for rapid energy replenishment, it visibly damages cycle life.

High currents generate more Joule heat, increase polarization, and accelerate mechanical stress on active materials and breakdown of the SEI layer, shortening lifespan.

State of Charge Range

Keeping the battery at a high state of charge or high voltage for extended periods also harms lifespan.

For long-term storage, maintain the SOC between 40% and 80%.

In daily use, setting the maximum charge limit to 90% or 80% can effectively extend cycle life.

Manufacturing Quality

The final cycle life of a battery depends on sophisticated manufacturing processes and quality control.

Factors like extreme production humidity/temperature, uneven electrode coating, poor alignment in stacking/winding, and inconsistencies between individual cells all impact cycle life.

Choosing reputable brands with advanced manufacturing processes is fundamental to obtaining long-life batteries.

How to Extend Battery Cycle Life

In practice, a battery’s cycle life is not fixed; it varies significantly based on user habits, ambient temperature, and charging/discharging methods. The good news is that you can extend your battery’s life with proper care. Here are the most practical and actionable strategies:

Maintain a 40-80% DoD Range

Deep discharges impose high stress on electrode materials, causing irreversible damage like structural expansion, delamination, and microcracks.

Using the battery within a 40-80% SOC range can significantly increase its lifespan.

For energy storage systems, cycling between 20% and 80% is most common.

Follow Manufacturer’s Recommended C-rate

Different battery chemistries can withstand different C-rates. Excessively high rates can cause overheating, high polarization, and lithium plating risks.

Adhering to the manufacturer’s recommended charge/discharge rates significantly extends life. Industrial ESS typically uses 0.25C to 0.5C rates to prolong life.

Always use the original charger or certified equipment.

Research by Paul Gasper’s team, published in the Journal of Energy Storage, involved accelerated aging tests on batteries from various manufacturers, with different chemistries (LFP vs. NMC) and designs. The results confirmed that cycle life is highly sensitive to usage conditions like temperature, DoD, voltage window, and C-rate.

Adopting these simple yet critical habits can significantly slow the capacity fade curve, keeping the battery at a higher usable capacity and ensuring a longer practical service life.

Conclusion

Against the global backdrop of accelerating renewable energy deployment, reducing resource extraction, and promoting sustainable development, extending battery cycle life not only saves costs but also reduces mining demands, decreases waste, and contributes positively to environmental and humanitarian causes.

Mastering the key principles outlined in this article–controlling DoD, avoiding high temperatures, minimizing fast charging, and maintaining reasonable C-rates can significantly enhance battery reliability and service life, making every kilowatt-hour of energy more valuable.

share