23 April, 2025

How to Design the Optimal PV String Configuration for Inverter Integration

In a photovoltaic (PV) system, proper string configuration is key to maximizing inverter efficiency, ensuring system stability, and achieving optimal power generation. Designing the best string-to-inverter scheme requires considering module specifications, inverter limits, and environmental conditions.

1. Understanding Inverter Input Constraints

| Parameters | Description |

| Max DC Input Voltage (Vdcmax) | Must not exceed the total Voc of modules in series under the lowest ambient temperature conditions. |

| MPPT Operating Voltage Range | Ensure the operating voltage remains within the specified MPPT voltage range at all times. |

| Rated Operating Voltage | The closer the operating voltage is to the rated value, the higher the conversion efficiency. |

| Max MPPT Current | Limit the total input current from parallel strings to stay within the inverter’s maximum current capacity. |

| MPPT Tracker Count | Modules with different orientations should be connected to separate MPPT channels. |

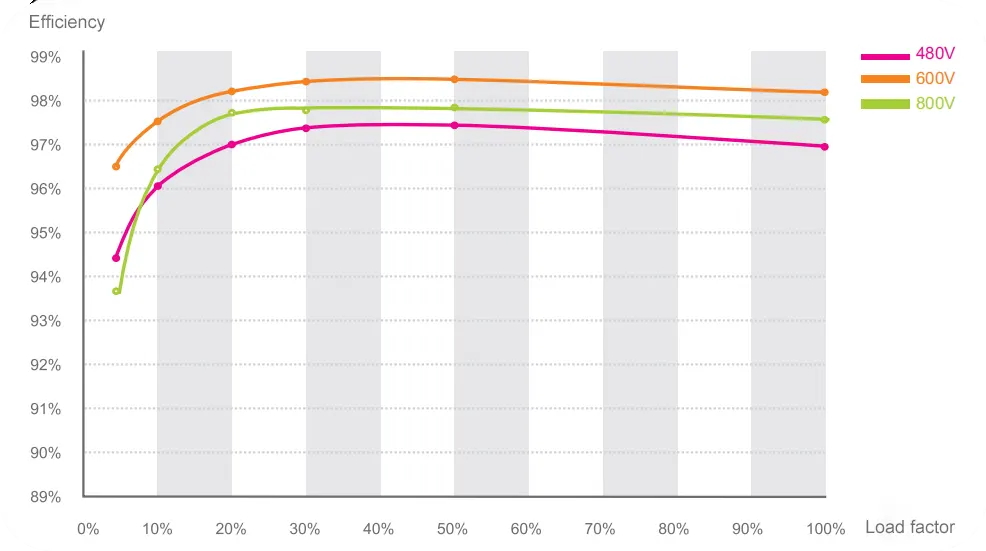

The inverter’s conversion efficiency is influenced by its operating voltage — efficiency decreases when the voltage is either too low or too high. The closer the operating voltage is to the inverter’s rated voltage, the higher the conversion efficiency. The graph below shows the efficiency curve of a 1100V three-phase inverter.

2. How to Calculate Optimal String Count?

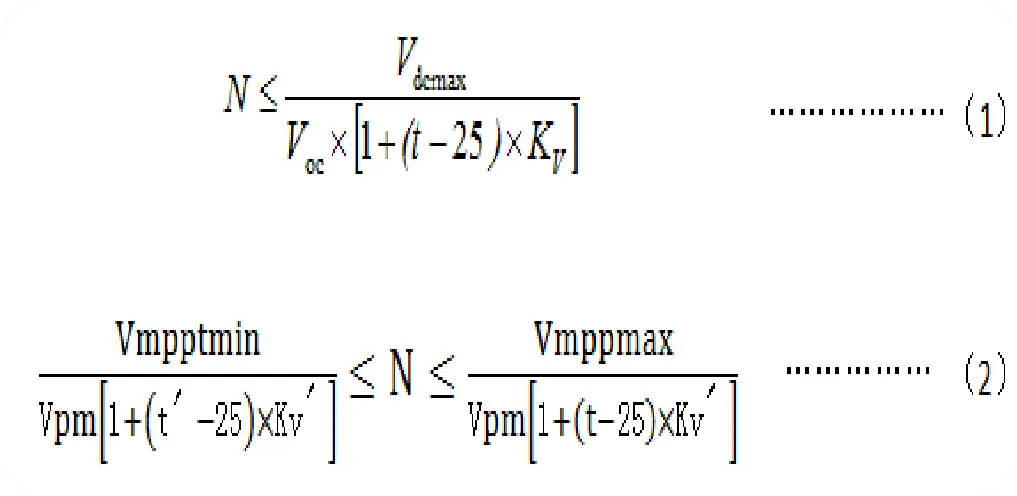

To ensure optimal inverter performance, the string configuration must satisfy the following two design conditions:

Condition 1: Total Voc ≤ Vdcmax

Maximum number of modules in series ≤ Vdcmax / Voc (at lowest site temperature)

Condition 2: Vmpp ∈ MPPT Voltage Range

Vmpp = Vpm×[1 + (T – 25)×Kv]

Where:

T = local maximum ambient temperature (°C)

Kv = temperature coefficient of voltage (typically negative)

3. Practical Case: 635W Module + 1100V Inverter

Module Specifications (STC):

Open-Circuit Voltage (Voc): 56.57V

Maximum Power Point Voltage (Vmpp): ~48V

Voltage Temperature Coefficient (Kv): -0.25%

Environmental Conditions:

Highest temperature: 50°C→Corrected Vmpp≈45V

Lowest temperature: -10°C → Corrected Voc = 61.5V

Inverter Specifications:

Max DC Input Voltage: 1100V

MPPT Voltage Range: 300V – 1000V

Rated Operating Voltage: 600V

Recommended String Count Calculation:

Maximum modules in series: 1100V / 61.5V ≈ 17 modules (for voltage safety margin)

Optimal operating voltage configuration: 600V / 48V ≈ 12.5 → Suggest 14 to 16 modules in series

Recommendation: 14–16 modules per string offer the best balance of efficiency and cost.

4. Design Optimization Tips

| Design Consideration | Recommendation |

| Cold Climate Regions | Prioritize verifying Voc under extreme low-temperature conditions |

| Different Module Orientations | Connect to separate MPPT trackers to avoid mismatch losses |

| Uniform String Count | Maintain equal module count per string to reduce voltage imbalance |

| Even Module Count | Simplifies wiring and reduces potential installation errors |

| Near Rated Operating Voltage | Keep Vmpp as close as possible to inverter’s rated voltage for maximum efficiency |

5. Why Is “Optimal Inverter Integration” So Important?

Enhanced System Efficiency: The closer the operating voltage is to the inverter’s rated voltage, the higher the conversion efficiency.

Reduced Wiring Costs: More modules per string → fewer total strings → less cabling required.

Lower Line Losses: Lower current leads to reduced thermal losses.

Increased Long-Term Yield: A well-matched system ensures long-term stability and better lifetime energy output.

6.Conclusion

Designing the optimal PV string configuration for inverter integration is a complex task that goes far beyond connecting more modules. It requires a thorough understanding of component behavior, inverter specs, environmental influences, and cost implications. Smart design leads to a smarter, more profitable solar system.

share